|

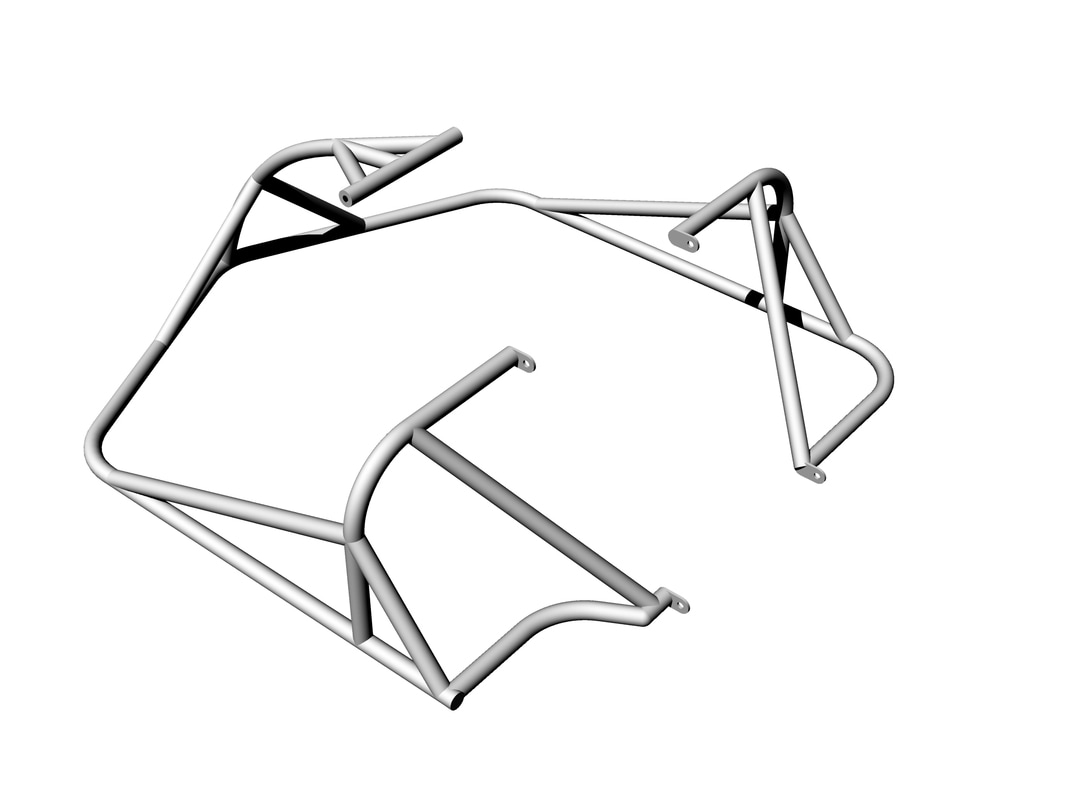

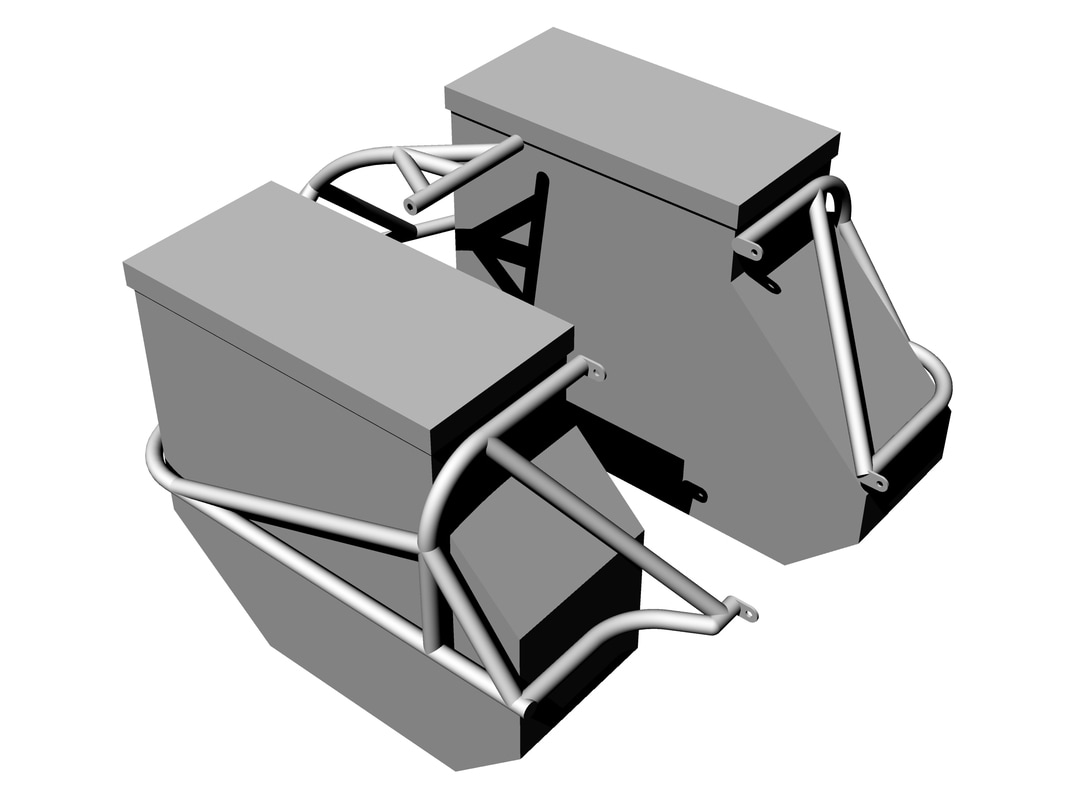

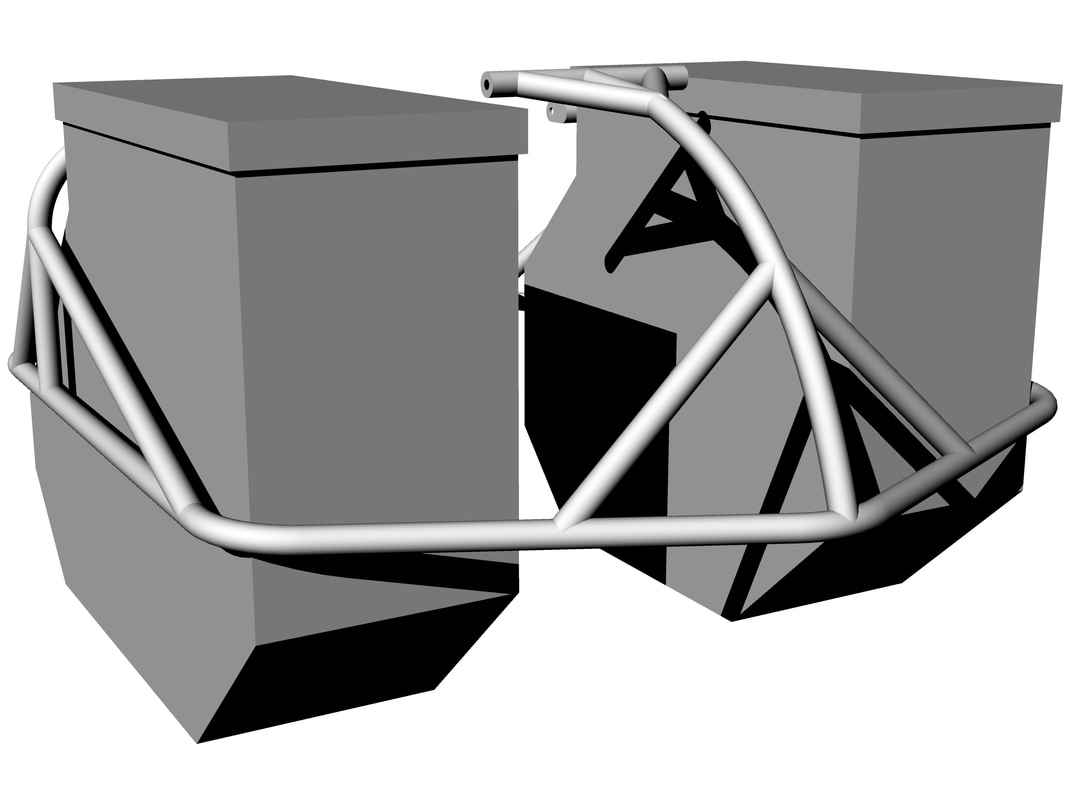

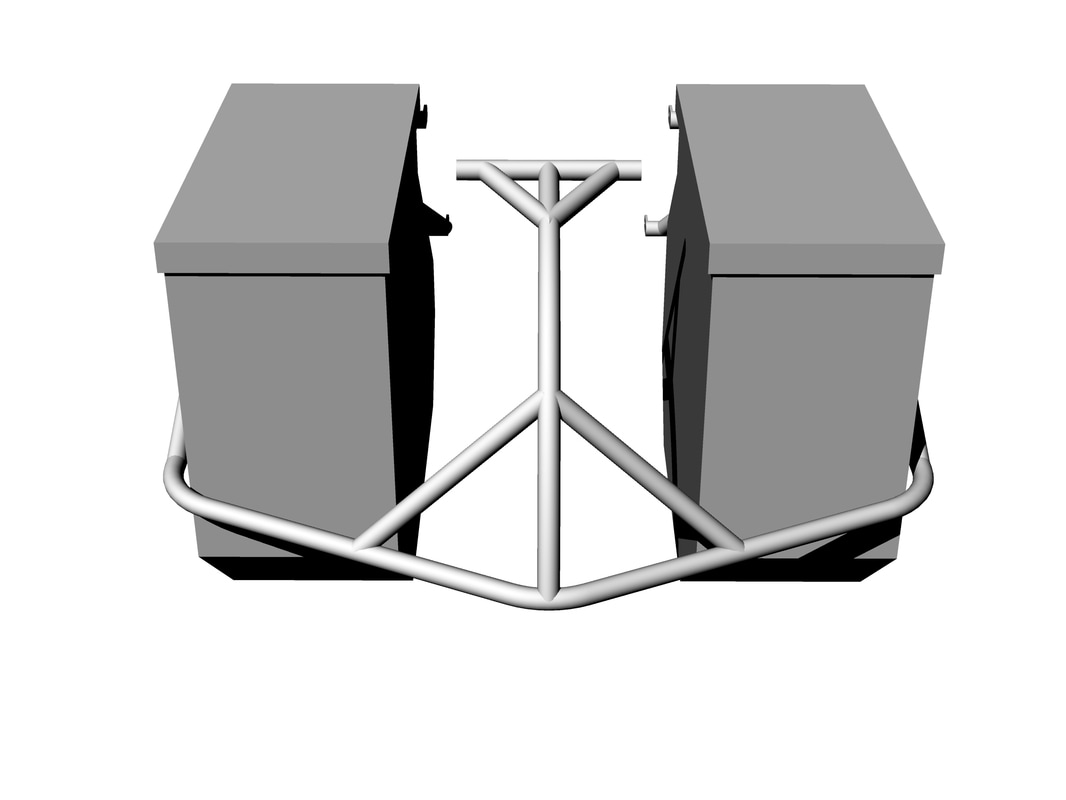

Having finalised the shape of the frame (including compensation for kickstart...) and fitted it to the bike I'm now able to start designing the luggage itself. This might seem a backwards way of thinking, but in fact makes the most sense. The key dimensions of the frame were that it could be no wider than the handlebars and could only come so far forwards before interfering with either moving parts or the ergonomics of the rider whereas the particular shape of the luggage is secondary, so long as it is large enough, doesn't interfere with any parts, and is convenient to attach and remove. Now that the frame is fixed, the luggage has been designed to fill the space between bike and frame and be removable through the gap left clear to the rear of the frame. Although the fittings to mount the luggage onto the frame is still being finalised there will be at least three attachment points to ensure the luggage is held rigidly. With the outlines of the luggage determined I've been able to start cutting and bending the thicker aluminium angle that will form the stronger edges of each box. The panels themselves will be lighter weight and riveted in place.

The technique for cutting the aluminium corners such that when folded to the correct angle the two edges met along their entire length for easy allly-welding took a while to perfect. The best method it seems is to cut a 43° wedge on the bandsaw if a 45° bend was desired. This allowed for the overlap at the very tip of the wedge where the bandsaw cut doesn't finish perfectly sharply, but instead as a rectangle with the width of the blade. With this 43° wedge removed the angle then bends perfectly to 45°. |

Archives

February 2017

Tags |